Kraków 2016-05-16

Internal combustion, piston, radial engine.

Star engines, classic ones, became the main tool of aviation development. However, at present they are already historical structures. They are still in production but are not being developed anymore. An example of the still produced engine is the WSK PZL Kalisz ASz-62 engine with a capacity of 1,000 HP. These engines have already been replaced by turbo-propeller engines.

The star engine was built in single, double and quadruple-star systems. Very rarely a triple star. It was not possible to create a successful 5-star engine. Single and double star structures were the most common. In general, the problem was the effective cooling of such an engine. These engines are cooled naturally by the flowing air. Liquid-cooled star engines have not been developed. The lack of a liquid cooling system resulted in the reduction of engine weight and simpler structure. As a result, the radial engine had a good weight-to-power ratio.

A single star was usually constructed in a 5-, 7- or 9-cylinder arrangement. 11-cylinder systems were not used due to the lack of space around the circumference of the engine body. The motor body would have to have an unnaturally large diameter and thus a large end face. The binary star engine system was usually 14 cylinders, 7 cylinders each in a star.

The pinnacle of the design of multi-star engines was the American Pratt & Whitney R-4360 Wasp Major engine used in nearly 30 types of aircraft. Its first launch took place in 1944, i.e. at the end of the Second World War, and was developed for combat aircraft. The Pratt & Whitney R-4360 engine was built from four 7-cylinder stars for a total of 28 cylinders. Each subsequent star is shifted by a certain angle in relation to the previous one. In this way, a spiral was created through which the cooling air flows relatively easily. The engine was supercharged and moved the adjustable propeller, the tips of which did not reach supersonic speed, unfavorable for effective operation. Although the engine was mechanically reliable, there were in-flight fires, especially on Boeing Stratocruisers. Each cylinder had two candles for a total of 56 candles. With so many cylinders, it was difficult to determine which cylinder was out of service due to spark plug failure. The manual method was used, i.e. touching candles with a finger to check if it was cold. An average overhaul of an engine used in civil aviation was performed every 600 hours. The engine had a capacity of 4,362.50 inches3 (hence the designation 4360), or approximately 71.49 liters. Despite one capacity, the engine variants had power from 1,970 kW to 2,834 kW, thanks to different fuel supply and supercharging systems. The most popular was the 3,000 hp (2,240 kW) variety, and from 1945 the 3,500 hp variety. The most powerful variant had 4,300 HP. The engine was relatively light and weighed about 1,580-1,755 kg, which gave about 2 HP from 1 kg of weight. By 1955, 18,697 Pratt & Whitney R-4360 Wasp Major engines were built. A new 4-blade adjustable propeller was developed for the engine. The Pratt & Whitney R-4360 Wasp Major engine was replaced by an Allison T56 turboprop engine.

In Poland.

The development of Polish aircraft engines was hampered by the lack of the automotive industry. The first Polish constructor was the engineer mentioned in the previous chapter. Henryk Brzeski. In the free Republic of Poland, Eng. Władysław Zalewski (January 28, 1892 - November 25, 1977).

Władysław Zalewski was born in 1892 in Warsaw and graduated from the prestigious Wawelberg technical school here. After the outbreak of the Great World War, he joined the 2nd Regiment of the Imperial Russian Aviation Service. At that time, he constructed the experimental S.Z.-1 aircraft. It was a two-seat four-lobe. After returning home, he devoted himself immensely to aviation. He studied the flight technique of the ornithoptera, i.e. the butterfly. He designed wing-beating aircrafts, just like birds. He also studied windmills. He worked at the organization of the Polish Patent Office and at the Aviation Research Center on establishing technical regulations for admitting new types to flight tests. After the Great World War, at the end of 1918, Władysław Zalewski was employed at the Central Aviation Workshop as head of the design office.

In 1920, the Polish Army expressed interest in a linear, two-seater, attack aircraft. In the spring of 1920, at the Central Aviation Workshop in Warsaw, the construction of the WZ-VIII De-That-Pe linear plane, designed by engineer Władysław Zalewski, began. De-That-Pe stood for the Department of Air Navigation. The WZ-VIII aircraft was the seventh construction by Władysław Zalewski, and the first Polish construction in the Second Polish Republic. In the period 1912-1937, Władysław Zalewski developed about fifteen of his own designs for gliders and airplanes. Due to the ongoing war with Bolshevik Russia, the work on the plane was slow. Just before the WZ-VIII De-That-Pe prototype was completed, in August 1920, it was accidentally damaged and remained in the hangar. In July 1922, Władysław Zalewski asked the CWL management to complete the construction. The consent was issued only at the turn of 1923/1924. The designer, however, had to make many modifications and changed the designation of the aircraft to WZ-VIII bis. But already in the spring of 1924, Władysław Zalewski was offered a design office at the Wielkopolska Aircraft Factory "Samolot" in Poznań. Władysław Zalewski supported the creation of WWS "Samolot", after the scandal with Frankopol. Ultimately, the designer did not move to Poznań. The WZ-VIII bis aircraft was not completed, and the construction was considered to be non-prospective.

On the other hand, a new WZ-X biplane by Władysław Zalewski was built, the first combat aircraft of Polish construction, which was flown in 1926 at Pole Mokotowskie. In 1927, three more planes were built. The first three planes had a Lorraine-Dietrich 12 Eb in-line, water-cooled, 12-cylinder "W" engine with a nominal power of 450 KM, take-off power of 478 KM. The engine was cooled by two Lamblin radiators located under the front part of the fuselage. The fourth WZ-X / IV aircraft had a 9-cylinder Gnome-Rhône 9A Jupiter radial engine, air-cooled, with 480hp. Fuselage fuel tank. Two-blade or four-blade propeller on WZ-X / IV.

Description to the photo: The Gnome Rhone Jupiter 9ab engine is a 480hp 9-cylinder engine from 1924.

After establishing Państwowe Zakłady Lotnicze, Eng. Władysław Zalewski was tasked with developing a bomber plane. It was to be an all-metal, 4-engine heavy bomber, designated PZL-3. The plane was not implemented due to the high cost of the program and little usefulness for the Polish Army at that time.

During the defensive war (1939), Władysław Zalewski ended up in England. He was still involved in aviation. After the end of the war, he founded a small mechanical workshop in London and later in Mildenhall (Suffolk), where he himself made prototypes of machines for plastic injection into molds. He was active until the last moments of his life. He designed and patented. He died in 1977 at the Bury St Edmunds Hospital in the East of England.

What interests us the most is the construction of aircraft engines by engineer Władysław Zalewski. In 1926, he built the first aircraft engine. It was a 5-cylinder radial engine, marked WZ-18, with 18 HP. The constructor used this engine to propel his own small plane "Kogutek".

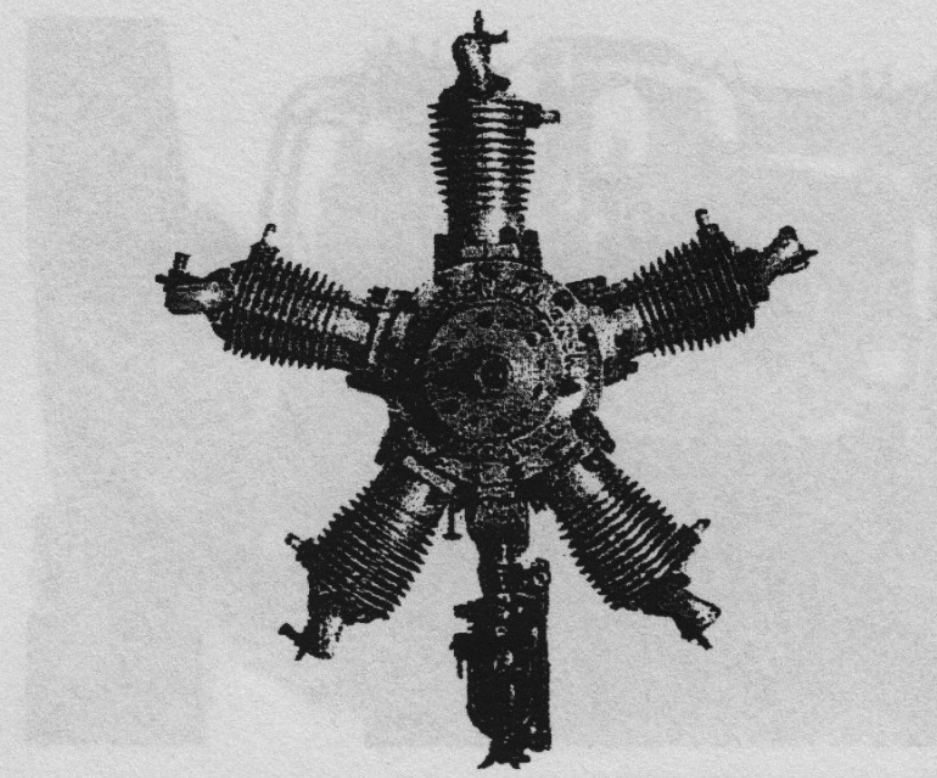

Description to the photo: Engineer Władysław Zalewski WZ-18, 18 HP, built in 1925.

Władysław Zalewski then built the WZ-7 engine, 80 HP, which was tested on the PZL-5 aircraft. Then the WZ-100 engines with 100 HP and the WZ-40 with 40 HP were created. However, these engines were not used in airplanes. In 1939, engineer Władysław Zalewski started building the WZ-25 engine, with a capacity of 25 HP, for his "Kogutek II" aircraft.

During this period, several other engine designs were built by Polish constructors. However, none of them were air-tested, much less serial production began.

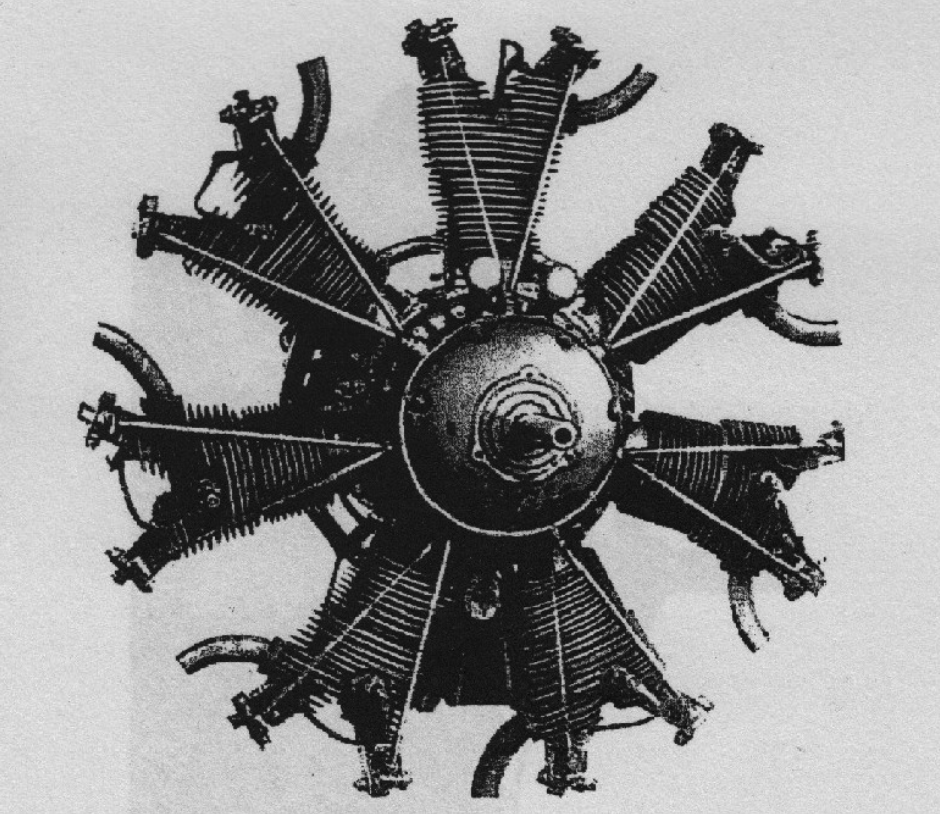

Eng. Franciszek Peter vel Franz Peter (1896-1968). His family came from Zaolzie. He was born in Vienna as an Austro-Hungarian citizen. During the Great World War, he served in the Austro-Hungarian aviation. Initially as a reconnaissance aircraft pilot, then as a fighter pilot. He flew mainly on Albatros D.III planes. He became a hunting ace. He ended the war with the rank of lieutenant and shot down six enemy planes. After the war, he decided to join the reborn Polish Army. As a pilot, he took an active part in the defense of Lviv against the Ukrainians. He was wounded during the fighting. In the Polish-Soviet war, he was the commander of the 6th Intelligence Squadron. He became an engineer and achieved the rank of major in the Polish Army. He worked in the Central Aviation Workshops (Zakłady) Lotnicze. He took care of aircraft engines. In 1929, he built a radial, 7-cylinder engine called "Peterlot" with 80 hp. Several pieces were built.

Description for the photo: Engineer Franz Peter Peterlot, 80 HP, 1929 year.

In 1933, together with Eng. And Sieńkowski, Franciszek Peter built a 90 HP in-line, 4-cylinder engine, named after the creators of "Petersen" and it was built in the number of 11 units. The engine was tested on a WK-3 aircraft. As the technical director of Wytwórnia Maszyn Precyzyjnych Avia, Franciszek Peter, together with W. Narkiewicz, developed the following engines: Avia P.4 100 HP and Avia 3 63 HP, which were tested on RWD-16 and PWS-40 Junak aircraft. Franciszek Peter died in Warsaw in 1968.

Among other Polish aircraft constructors, one should mention Eng. Tadeusz Tański (March 11, 1892 - March 26, 1941 - murdered in Auschwitz by the Germans). He received a thorough technical education in France. He mainly dealt with land vehicles and their engines. However, he was no stranger to aircraft engines. In France in 1916, he built the largest aircraft engine in the world at that time, a 12-cylinder, 520 HP with a horizontal H-shaped cylinder arrangement. In 1918, he built a rotary, four-cylinder, radial, two-stroke engine, marked "Wir", intended for light aircraft. Tadeusz Tański, Eng., Was respected in the French technical environment and obtained patents there. In 1919, he returned to the reborn Republic of Poland and he did great service as a constructor. In 1929, engineer Tadeusz Tański constructed a seven-cylinder aircraft engine TK-7, 80 HP, in a star system, air-cooled. The engine did not enter serial production.

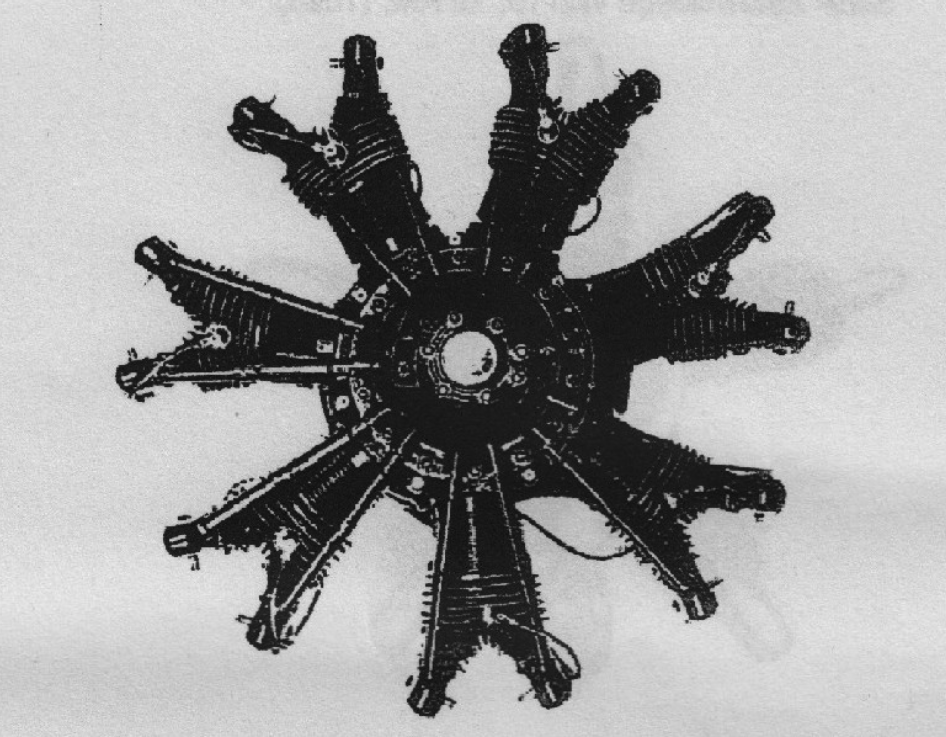

Among the successful engineers, one should mention Eng. Stanisław Nowkuński (November 10, 1903 - July 30, 1936). He was born in St. Petersburg. After graduating from high school in 1921, he came to Poland and began studies at the Faculty of Mathematics of the University of Warsaw. A year later, the Faculty of Mechanical Engineering of the Warsaw University of Technology moved. Already during his studies he was active in the Warsaw Aero Club. In 1927 he became an engineer. After graduating, he worked at WWS "Airplane" in Ryszard Bartel's team. He returned to Warsaw and started working at the Polish Skoda Works (from 1935 Państwowe Zakłady Lotnicze - Wytwórnia Motników). The first design work by Eng. Stanisław Nowkuński was the 88 kW 7-cylinder radial engine G-594 "Czarny Piotruś", built in 1930. It had the power of 120 HP. 3 copies were built. The engine was tested on Bartel BM-4 and RWD-8 airplanes.

Description to the photo: The Stanisław Nowkuński G-594 "Czarny Piotruś" engine, radial, 7-cylinder, 120 HP (88 kW), from 1930.

In 1931, Eng. Stanisław Nowkuński has developed the G-1620 A Mors I 9-cylinder radial engine with a power of 250 kW. The engine was made serine. 53 were built and mounted on Lublin R.XIII F planes. In 1933, a version of the G-1620 B Mors engine was also created, with a nominal power of 410 hp (346 kW) and a take-off 470 hp. Mass production was started and 100 units were built. These engines were mounted on RWD-14 "Czapla" aircraft.

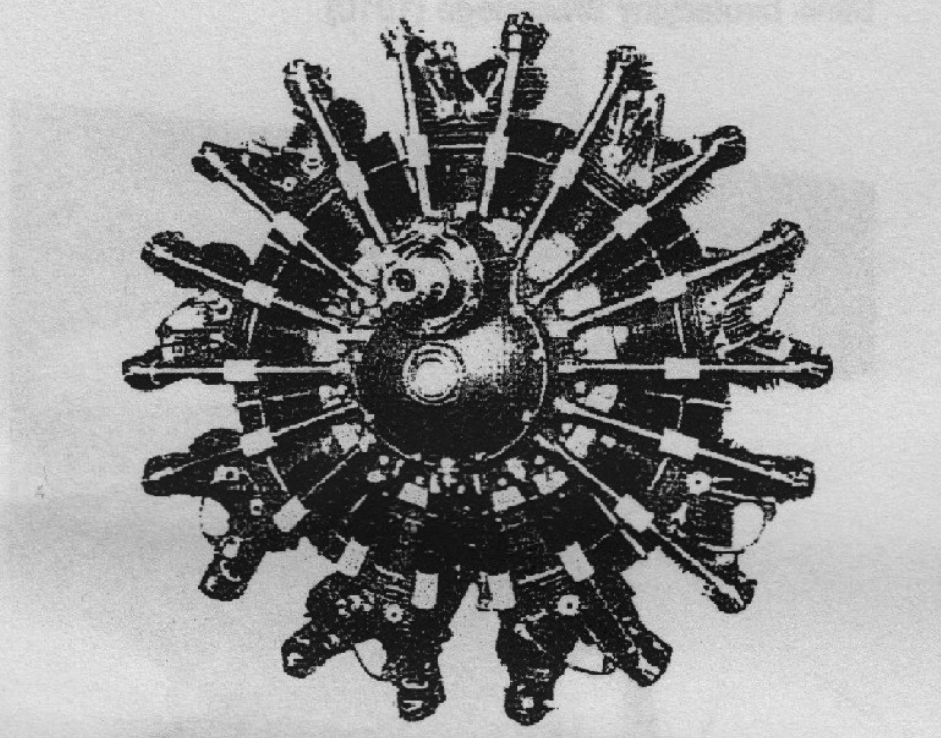

In 1932, Eng. Stanisław Nowkuński together with Eng. Władysław Łoziński, they started work on the radial engine marked GR-760 with a power of 290 HP (213 kW). The engine was designed specifically for the Challenge 1934 aircraft. The GR-760 engine was developed with a reducer. There was a 9 cylinder. The engine had a very good weight to power ratio; 0.54 kg / KM. Six engines were built and mounted on RWD-9 aircraft. In the mentioned competition, the first two places were taken by RWD-9 planes with GR-760 engines. The French and Italians wanted to buy a license for the engine. However, it was necessary to carry out additional trials and tests that were not performed.

Description to the photo: The engine of engineer Stanisław Nowkuński, type GR-760, 290 HP, 9-cylinder, from 1934, was mounted on RWD-9 aircraft.

Written by Karol Placha Hetman