Internal combustion-piston engine in Poland, after 1944.

After World War II, the development of medium and high-power piston engines was practically stopped. Only low-power internal combustion engines remained in development. This was due to the revolutionary development of turbojet engines, followed closely by turboprop engines. Unfortunately, the Polish Aviation Industry has practically dropped out of the world leaders. As a country influenced by the CCCP, our economy has lost its importance.

GAD-500.

Nevertheless, there were many talented designers in Poland. One of them was Eng. Stefan Jerzy Gajęcki. He was the designer of a series of successful engines, designated GAD, which were used primarily in motor boats. Stefan Gajęcki himself was also a constructor of sliding boats and a motorboat sports competitor. The GAD 500 engine was intended to be used to drive a small-engine car that could motorize Poland in the second half of the 50s. The same engine was intended to be used to drive the Pegaz moto-glider. The standard GAD 500 engine has two cylinders, a displacement of 496cc with a piston diameter of 70.2mm, and a stroke of 64mm. Compression 7.7: 1. The power is 19-23 hp at 4,500 rpm. The plan was to increase the capacity and compression ratio for the aircraft engine, to use aircraft carburetors and better fuel. It was planned to achieve a power of 30-32 HP. The constructor built the prototype of the XL-GAD engine in 1948. Flat 4-cylinder (boxer) system with 31 HP. The engine was tested at the Institute of Aviation. It turned out that the engine vibrated too much at high speed. The engine was intended to be refined, but the Pegaz glider program was abandoned.

Wiktor Narkiewicz

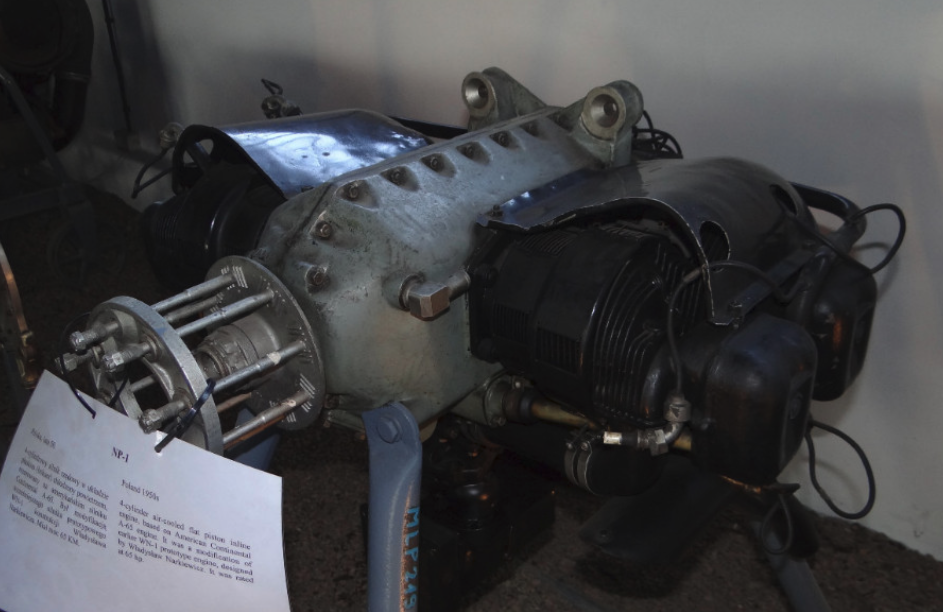

The constructor, who had extensive pre-war experience, was engineer Wiktor Narkiewicz, who after the war worked in CSS (Central Aircraft Study). First, he designed an engine that was designated WN-0. It was a 4-cylinder flat engine, which used the cylinders of the Czech Walter Mikron engine. The engine was not built. Then, in 1949, Wiktor Narkiewicz designed another 4-cylinder engine with a planned power of 65 HP. The design was based on the American Continental A-65 engine. Boxer, flat, air-cooled engine. 3 pieces were built. The engine was tested on a Piper Cub plane. The engine was intended to power the Żak-2 aircraft. The engine was also installed on the PZL-102 Kos aircraft in 1959. However, more powerful engines were used in the PZL-102 Kos aircraft. The WN-1 engine was modified and a variant was created, designated NP-1. On the basis of the WN-1 engine, a 2-cylinder variant of the A-35, with a capacity of 35 HP, and a 6-cylinder variant of the NP-2, with a capacity of 95 HP, were planned. Both projects were never implemented.

Then in 1950, Eng. Wiktor Narkiewicz started working on 7-cylinder radial engines. The first was WN-2. This engine was modeled on the American Jacobs R-755 (L-4) engine, which powers the Boeing Stearman, among others. The WN-2 engine has a power of 280 HP. The engine turned out to be successful. In 1950, three prototypes were built. However, the program was halted as the engine requirements were increased. Thus, in 1952-1954, the WN-3 engine, with a capacity of 330 HP, was created and was used to power the TS-8 Bies training planes in 1955. The engine was produced by PZL-Kalisz, where 329 units were built (1957-1960). The WN-3 engine was used to power the PZL MD-12 transport aircraft, when the Russians refused to deliver the ASz-21 engine.

Basic engine data: The WN-3 engine is low, medium power, without supercharger (compressor) and reducer. Single-star, 7-cylinder, 4-stroke, air-cooled. It drives a 2-blade variable-pitch propeller. Starting the engine with compressed air. Take-off power is 315 hp (232 kW) at 2,350 rpm, sustained for 15 minutes. The engine has an instantaneous maximum power of 330 hp (243 kW) at 2,500 rpm, which is maintained for 3 minutes. Rated power 285 HP at 2,250 rpm. Displacement 13.4 dcm3, compression ratio 6.2: 1, dry weight 255 kg (240 kg). The minimum engine speed is 500-600 rpm. The transition time from "low gas" to starting power is 3 seconds. The inter-repair period is 400 hours.

On the basis of the WN-3 engine, a development version designated WN-5 was developed. It was an engine equipped with a reducer and compressor (supercharger). It was supposed to have 350 hp, and in addition, with the increase in flight altitude, the power loss was to be much smaller.

The PZL Kalisz design office, based on the WN-3 engine, has developed an air-cooled radial engine with a take-off power of 360 HP (265 kW) and a rotational speed of 2,700 rpm. The engine was designated K-5. The compression ratio in the engine was increased from 6.2: 1 to 6.5: 1. The engine speed was also increased by 350 rpm. The engine was started using an electric starter. The engine is also led to the outside, in order to connect external devices, e.g. agricultural aviation equipment. Power consumed up to 34 HP (25 kW). The mass of the K-5 dry engine is 261 kg. The first launch on the dynamometer took place in December 1972. The engine passed the first series of tests, but further work was abandoned due to the lack of interest in an engine of this power. The K-5 engine, anticipated to drive agricultural aircraft, would be too weak, but would be perfect for light aircraft.

The WSK PZL WN-3 engine version was adapted to drive helicopters. The engine received the designation WN-4. The main designer was MSc. Wiktor Narkiewicz. A few copies were built and tested at the Institute of Aviation in 1956-1957. The engine has a maximum power of 320 HP (235 kW) and a nominal power of 300 HP. Of this power, 20 HP (15 kW) was taken by a fan, which was used to cool the engine. The engine was a successful design and promised a long and reliable service. The engine was used to drive the prototype BŻ-4 Żuk helicopter. The helicopter was developed at the Institute of Aviation in the Helicopter Design Office, established in 1954. Initially, it was designated GIL-4, which was changed to BŻ-4 Żuk. Its designer was Eng. Bronisław Żurakowski (brother of the famous tester of English and Canadian airplanes, Janusz Żurakowski). The helicopter was designed in a single-rotor system with a modification of the Hiller system with an additional steering rotor. MSc. Wiktor Narkiewicz also developed an automatic friction clutch in the drive unit, for which he was granted the employee patent No. 39750.

Written by Karol Placha Hetman